Hours: 4

Over the last couple weeks I've been studying other builder's blogs, reading pages and pages of Van's Airforce articles / threads and generally trying to get a handle on best practices for working with CS-3204 B-2 (Seal Pro) for sealing up the gas tanks. I've accumulated popsicle sticks, gloves, acetone, mixing bowls, various (cheap) brushes, applicators, paper towels, ink brayers, etc. in preparation for working with the smelly gooey mess. Today I finally dived in- yes it is stinky, gooey, and not that much fun to work with.

I started out by sealing up the mandrel holes in the end ribs with AN470-AD6 rivets. The rivets supplied with the kit were length 6 which is overkill for plugging a hole, so I cut them down to a 5 using my rivet cutter. I was able to wet set them using my C-Frame and a heavy hammer.

Next I riveted on the fuel flanges. I was going to use the squeezer, but the rivets were too close to the neck of the flanges for the squeezer to fit so I ended up using the rivet gun and bucking bar. The procedure I used was to butter the back of the fuel flange and place it on the rib (the sealant holds it in place). Then I dabbed sealant on the rivet holes and inserted the rivets. Then I buttered the shop side of the rivets before setting the rivets with the rivet gun. After setting all the rivets I went back and dabbed on more sealant for good measure.

Here's what I got done before the first batch started getting a little too stiff to easily apply. I was trying to make it look pretty, but now I'm thinking I'll be happy to settle for just making it leak free. I'll have to work faster in future build sessions. The temperature was in the mid 40's in the garage this afternoon.

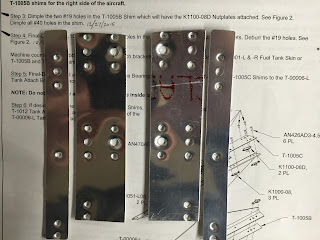

Here's some of the supplies. The electronic postal scale I just purchased at Office Max died so I pulled out my trusty gram scale that I normally use for building indoor models. Sometimes old analog tech rules ;-) I'm using paper bowls for mixing- easier to mix in a bowl than a cup. I'm using acetone for clean up.