Section:

Hours: 6

I borrowed / rented electronic scales from the Placerville EAA Chapter. The scales come in a solid shipping box and include a couple of ramps for rolling the wheels up onto the scales.

I assembled all the access covers, put in all the interior (seats, carpeting, side panels), topped off the engine oil and added the wheel pants so the weight would reflect the actual flying condition of the airplane.

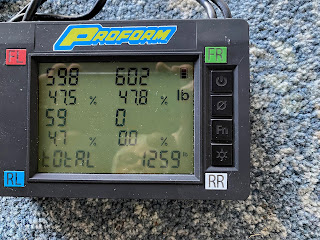

I enlisted some friends from the airport to help lift the tail onto some saw horses to put the airframe in flying attitude. After carefully adjusting the tail height to level the canopy rails, we and rolled the airplane onto the scales. Unfortunately, on the first try I forgot to push the tare button before we rolled the wheels onto the scales so we had to roll the airplane off the scales and start over. Lesson learned...And here is the result: